Understanding The Types of Corrugated Boxes

Choosing the Right Corrugated Box for Your Product

Who Knew There Were So Many Types of Corrugated Boxes? (We Did)

Corrugated boxes are stronger than you might think. Their secret? It’s all in the fluting. If that sounds confusing, don’t worry—we’re here to break it down. By the end of this post, you’ll know exactly which box to pick for shipping your products safely. Let’s get started.

What is Fluting, Anyway?

Fluting is the wavy layer inside corrugated cardboard, sandwiched between flat sheets called linerboard. This design gives the box strength, rigidity, and a bit of cushioning to protect what’s inside.

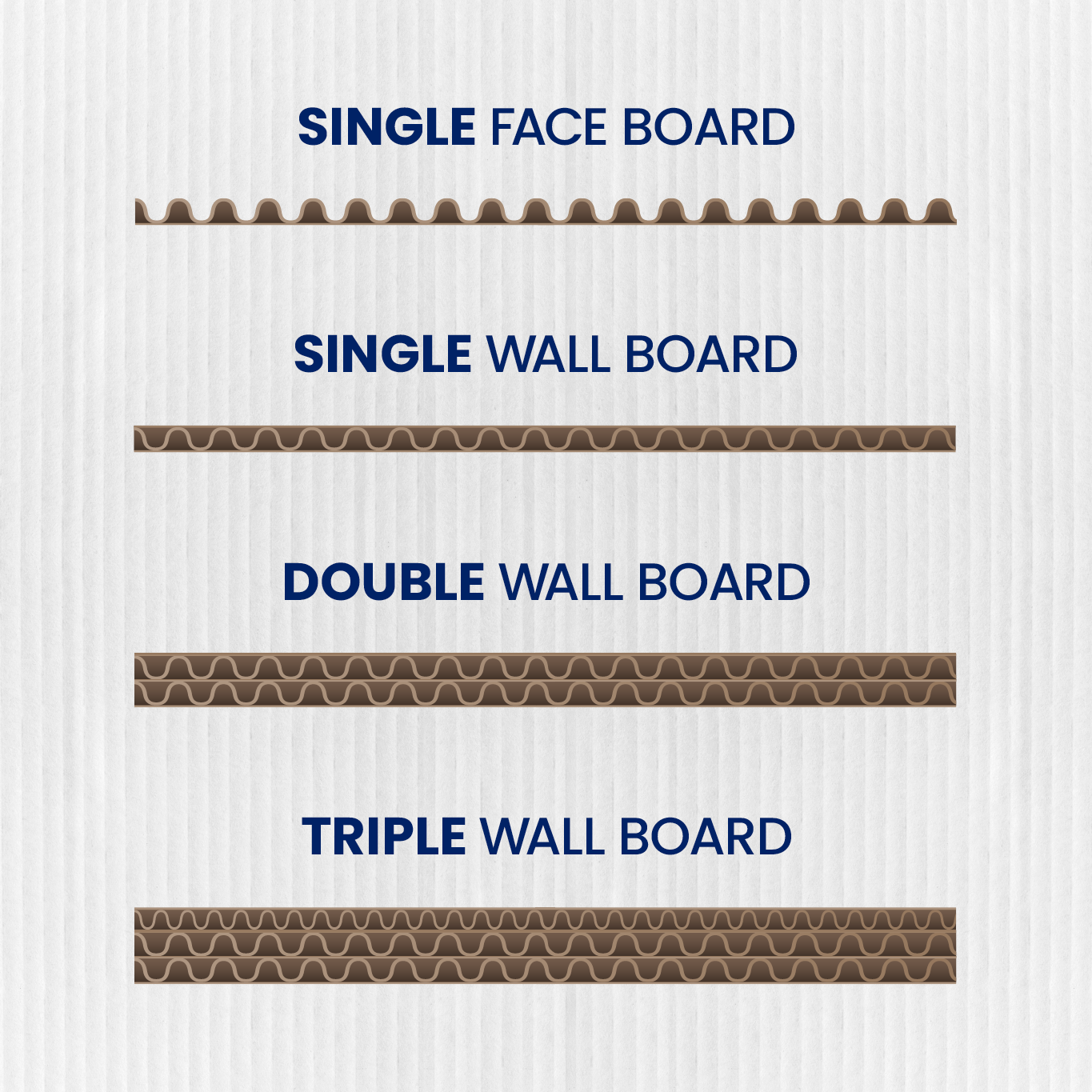

Adding Extra Protection

Fluting isn’t the only factor that makes a box sturdy. The number of walls—single, double, or triple—plays a big role in strength, offering extra protection for items that need special care during shipping. Additionally, the thickness of the liner enhances durability. A higher-grade liner creates a more rigid box, providing better support for heavier items and improving print quality for a sharper look. Doubling or tripling the board further boosts protection and capacity, ensuring your goods stay secure.

What Does That Mean for You?

It’s simple:

- Single-wall boxes: Ideal for light to medium-weight items, typically up to 65 pounds for palletized shipments or 32 pounds for parcel. Use a standard 32C liner or upgrade to a heavier liner for added strength.

- Double-wall boxes: Great for heavier items above 65 pounds, offering increased protection and weight capacity.

- Triple-wall boxes: Perfect for very heavy loads, handling hundreds of pounds with superior durability.

Choose the right wall type and liner grade to keep your products secure during shipping.

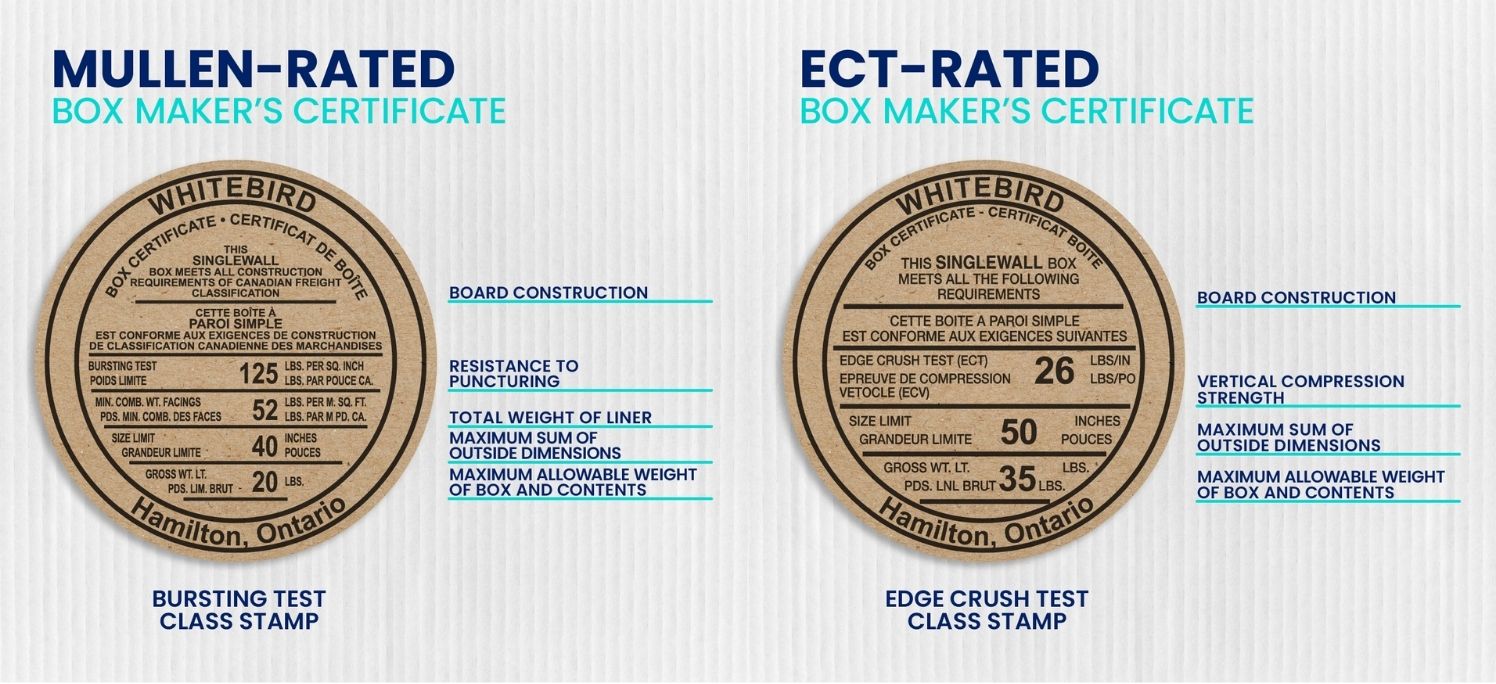

How Do I Know What Box I’m Using?

Understanding Box Certificate Stamps

Check the bottom of any good corrugated box, and you’ll find a stamp. This stamp tells you the box’s strength, including:

- Whether it’s single, double, or triple wall.

- The ECT (Edge Crush Test) or Burst Test rating.

- The weight and size limits.

Here’s an example of what to look for:

These stamps help you confirm your box meets your freight carrier’s rules. That means safer packages, fewer rejections, and less hassle with claims. Most carriers provide a chart with their minimum box requirements, like this one:

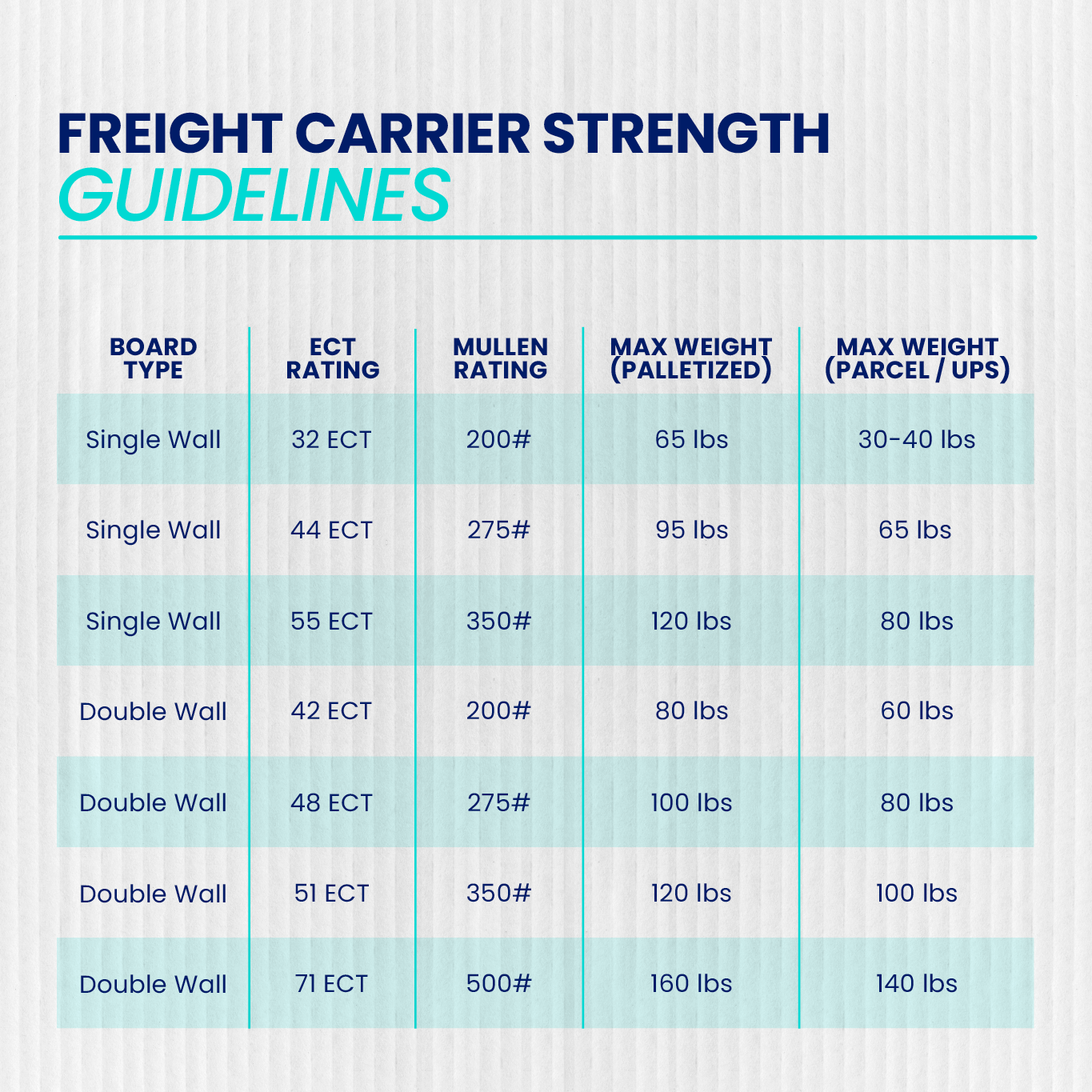

One More Thing to Know

Shipping requirements vary. Individual parcels have different rules than palletized shipments. Check your carrier’s guidelines for weight and ECT ratings based on how you’re shipping. Here’s a handy chart to compare:

10 Steps to Pick the Perfect Corrugated Box

Choosing the right box isn’t just about size. It’s about keeping your product safe, saving on shipping, and making your customers happy. Here’s how to do it:

- Measure Carefully - Get the exact internal dimensions—length, width, and height. A tight fit keeps items secure. Want tips? Read our post, How to Measure Corrugated Boxes (A Simple Guide To Box Measurements).

- Plan for Cushioning - Leave room for padding like bubble wrap or Kraft counter rolls. Your box needs to hold everything comfortably.

- Pick the Right Style - A standard brown box (Regular Slotted Carton) covers most shipping needs — but that’s just the start. Whitebird also offers a full range of specialty boxes, including multi-depth, tall, long, and heavy-duty options. Need something unique? Our sales team can get you custom boxes tailored to your brand and product.

- Match Strength to Weight - As we said, single-wall boxes handle lighter items, while double or triple walls are better for heavier or fragile products. Choose based on your product’s needs.

- Think About the Trip - Will your box go through multiple hands or rough conditions? Individual parcels need different boxes than palletized shipments. Pick a stronger box for tougher journeys.

- Consider the Environment - If your products are sensitive to heat, humidity, or moisture, choose specialty boxes or add protective liners to keep them safe.

- Test Your Packaging - Do a drop test before shipping. This is key for fragile or high-volume items to make sure your box holds up.

- Check Stacking Strength - If boxes will be stacked on a pallet, ensure they can handle the pressure. Look at the ECT rating on the box certificate stamp.

- Optimize for Cost - Bigger isn’t always better. A box that’s too large wastes space and increases shipping costs. Find the right balance.

- Work with Whitebird - We’re a Canadian packaging supplier with a wide range of corrugated boxes and expert advice. Let us help you find the perfect solution for your business.

Get Everything Your Business Needs

Whitebird does more than just boxes. We offer packaging equipment, janitorial supplies, and everything else to help your business run smoothly. Ready to find the right corrugated boxes? Call our team at 800-263-2128 to talk to an expert.